| Items |

28201

10 Feet (ft) Length and 230 Volt (V) Voltage Right Hand Sweep-in Belt Recovery System with Air-Wash Abrasive Cleaner (AWAC)

Price $86,245.00

|

28203

10 Feet (ft) Length and 460 Volt (V) Voltage Right Hand Sweep-in Belt Recovery System with Air-Wash Abrasive Cleaner (AWAC)

Price $86,245.00

|

28200

10 Feet (ft) Length and 230 Volt (V) Voltage Left Hand Sweep-in Belt Recovery System with Air-Wash Abrasive Cleaner (AWAC)

Price $86,245.00

|

28202

10 Feet (ft) Length and 460 Volt (V) Voltage Left Hand Sweep-in Belt Recovery System with Air-Wash Abrasive Cleaner (AWAC)

Price $86,245.00

|

27970

20 Feet (ft) Length and 230 Volt (V) Voltage Right Hand Sweep-in Belt Recovery System with Air-Wash Abrasive Cleaner (AWAC)

Price $94,435.00

|

|

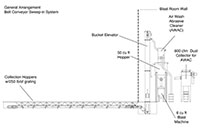

Description

|

N/A

For use with heavy (steel) and coarse-mesh abrasives

Belt Conveyor Systems include:

Belt conveyor 12" wide unit with metering hoppers, 250 lbs per square foot grating, bucket elevator assembly (4" wide belt) (1.5 HP motor) with integrated under speed monitor, air-wash abrasive cleaner, RPH dust collector (for abrasive cleaner ventilation only), 50 cu ft storage hopper, 6 cu ft industrial blast machine package, and NEMA-12 electrical control panel assembly. Price includes one-day start up supervision including travel expenses within the continental USA. Start up must be scheduled within one year of purchase.

|

|

Brands

|

N/A

Apollo Clemco®

|

|

Grating Rating

|

N/A

250 lb/ft²

|

|

Storage Hopper Size

|

N/A

50 ft³

|

|

Length

|

N/A

10 ft

|

N/A

10 ft

|

N/A

10 ft

|

N/A

10 ft

|

N/A

20 ft

|

|

Voltage

|

N/A

230 V

|

N/A

460 V

|

N/A

230 V

|

N/A

460 V

|

N/A

230 V

|

|

Number of Phase

|

N/A

3

|

|

Frequency

|

N/A

60 Hz

|

|

Orientation

|

N/A

Right Hand

|

N/A

Right Hand

|

N/A

Left Hand

|

N/A

Left Hand

|

N/A

Right Hand

|

|

Width

|

N/A

12 in

|

|

Includes

|

N/A

- Abrasive/media to be used: Heavy abrasives: Steel and Coarse-mesh

- Recovery unit: Belt conveyor unit with metering hoppers

- Bucket elevator for mechanical recovery included

- Dust collector: Ventilates abrasive cleaner. Separate blast room dust collector must be ordered.

- Industrial blast machine: 6 cu ft Industrial Blast Machine Package

- Operator safety equipment included

- Electrical control panel included

- Start-up supervision: 1-Day start up

|

|

Additional Information

|

N/A

Recovery system technologies are engineered to suit specific abrasive/media types. Best performance is achieved when the recovery technology is suitable for the abrasive/media to be used and when a dedicated dust collector is installed to ventilate the abrasive/media cleaning system. Abrasive cleaner/reclaimer dust collection is especially critical when using aggressive abrasives, such as, aluminum oxide, silicon carbide, garnet, and others.

|

|

Note

|

N/A

The dust collector provided with these systems is to ventilate the air-wash abrasive cleaner. A separate dust collector must be installed to ventilate the blast room. The blast room dust collector must be purchased separately.

|